Product Description

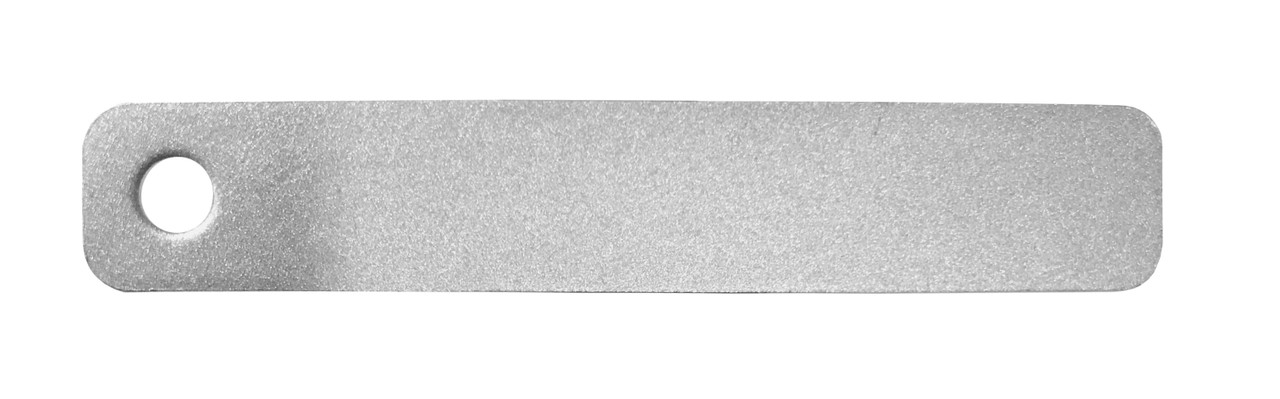

Corrosion Coupons

DATA SHEET | COUPON HOLDER DATA SHEET

Accurate monitoring of corrosion rates in any environment is critical when viewed in terms of the maintenance and repair costs associated with corrosion and material failure. Test coupons provide an inexpensive means of on-line monitoring that will allow you to effectively measure the corrosivity within your system. By observing the mils-per-year corrosion rate of an exposed coupon, valuable information can be provided regarding the material’s life expectancy.

Advantage Controls can provide coupons in any material you need. Coupons are stenciled with alloy and sequence numbers for proper identification. Mill test reports, identifying element compositions of materials used, are provided on all orders. The following coupons are the most commonly used in corrosion testing.

Corrosion Testing, Why?

Corrosion tests are conducted for a number of reasons, some of which are:

1. To provide an insight into corrosion mechanisms.

2. To compare resistance of one alloy to another under standard conditions (in alloy development work for example).

3. As a quality control test for a given heat of alloy.

4. To provide a basis for estimating service life of process equipment. The discussion which follows relates primarily to reason # 4, although the same principles apply in tests conducted for other reasons.

Type of Tests

Data of value in estimating the probable service life of a piece of process equipment can be generated in a number of ways.

1. Operating Experience - The most reliable information is generated by actual operating experience with equipment in identical service. In a sense the equipment is being used as a large, complex, expensive coupon. This is a costly and slow testing method, especially when data on several materials is needed.

2. Model Equipment - Model equipment installed parallel with actual equipment or in a small scale (pilot plant) operation can generate information almost as reliable as full scale equipment. Care must be exercised to assure that important variables are adequately simulated.

3. Coupons - Field - Coupons exposed in operating equipment are widely used. Care must be taken to install the coupons so that they are exposed to the corrosive conditions of interest.

4. Coupons - Laboratory - Coupons exposed to laboratory solutions from plant operations, or less reliable synthetic solutions which approximate the chemistry of plant streams, generate useful information if the tests are properly designed and conducted. Such tests allow study of the affect of changes in process chemistry on corrosion.

5. Instrumental Test Methods - Advanced methods, including electrical resistance and linear polarization scans, are valuable additions to corrosion testing methods. They can generate a continuous record of corrosion rate. They also can be used to gain insight into corrosion mechanisms. The precautions noted with regard to coupon tests also apply with these methods.

Coupon Mounting

Coupons should be mounted in such a way that they are securely held and are electrically isolated from contact with all other metals (except when the purpose of the test is to study galvanic corrosion). Mounting materials (brackets, bolts, etc.) and insulating materials should be selected to be fully resistant to the environment. Failure of any of these components will lead to loss of data or loss of electrical isolation.